AAAC (All Aluminium Alloy Conductor)

AAC conductor is a monometallic conductor, mainly used for short spans and for connection of electrical substations.

AAAC Data Sheet

AAAC (All Aluminium Alloy Conductor) is a high-performance overhead conductor designed for power transmission and distribution. Engineered with a superior aluminum-magnesium-silicon alloy, AAAC offers exceptional conductivity, mechanical strength, and corrosion resistance. Ideal for environmentally sensitive regions, it is a sustainable and efficient choice for modern energy needs.

Key Features

- Lightweight Design: Easier handling and installation compared to other conductors.

- High Corrosion Resistance: Perfect for coastal and industrial areas.

- Enhanced Conductivity: Optimized for efficient power transmission.

- Durability: Superior tensile strength and weather resilience.

- Eco-Friendly: Fully recyclable and environmentally sustainable.

Engineering of the Material

AAAC (All Aluminium Alloy Conductor) is a high-performance overhead conductor designed for power transmission and distribution. Engineered with a superior aluminum-magnesium-silicon alloy, AAAC offers exceptional conductivity, mechanical strength, and corrosion resistance. Ideal for environmentally sensitive regions, it is a sustainable and efficient choice for modern energy needs.

- Material Composition: The alloy contains carefully balanced proportions of magnesium and silicon, enhancing its tensile strength while maintaining excellent conductivity.

- Thermal Stability: The conductor can withstand high operating temperatures (up to 90°C) without significant loss of performance, making it ideal for regions with fluctuating climatic conditions.

- Fatigue Resistance: The advanced engineering process ensures the material is resistant to fatigue caused by mechanical stress and vibrations, enhancing its lifespan.

- Environmental Adaptability: The alloy is highly resistant to corrosion, particularly in saline or polluted environments, reducing maintenance requirements and ensuring reliability over decades.

The engineering process incorporates advanced metallurgical techniques to produce a uniform grain structure, optimizing the conductor’s strength-to-weight ratio and ensuring consistent performance across its entire length.

Applications

- Overhead power transmission lines.

- Urban and rural distribution networks.

- Coastal and industrial installations.

- Renewable energy projects such as wind and solar farms.

Advantages

- Improved Efficiency: High electrical conductivity reduces power loss.

- Longer Lifespan: Resistant to environmental and mechanical wear.

- Cost-Effective: Lower operational costs due to reduced maintenance needs.

- Sustainability: Fully recyclable material contributes to green energy initiatives.

Technical Specifications

Parameter

Material

Conductivity of the Material

Downloadable resources

Downloadable resources

Details

Aluminium-Magnesium-Silicon Alloy

52.5% IACS (International Annealed Copper Standard)

Downloadable resources

Downloadable resources

Compliance & Certifications

- Conforms to international standards: IEC 61089, ASTM B399, and IS 398.

- Certified for high-performance operations in diverse climatic conditions.

Product Variants

Variant

AAAC 16

AAAC 50

AAAC 150

AAAC 400

Cross-Section (mm²)

16

50

150

400

Weight (kg/km)

43

135

415

1110

Breaking Load (kN)

4.5

13.2

37.6

101.2

Custom

Available on request. here

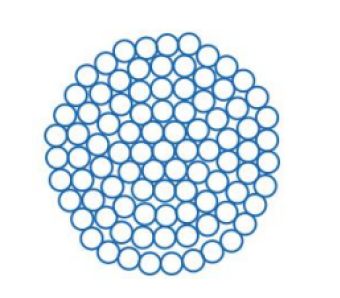

Visual Representation